objectives of supply chain management

Supply Chain Management highlights the importance of collaboration between suppliers, manufacturers, distributors, and customers, leading to better communication and coordination. This can be a significant advantage in todays market where speed and customer service are paramount features for remaining competitive. Maximize your resources and reduce overhead. Ethics has become an increasingly important aspect of supply chain management, so much so that a set of principles called supply chain ethics was born. The objectives of SCM include optimizing efficiency, minimizing costs, increasing customer satisfaction, and providing a competitive advantage to firms. Operational Accounting: Accounting for a company that focuses on planning, directing, and controlling of daily activities by their costs and eliminating waste. Customer forecasting is an important task that analysts must perform well to determine the current demand and what it will be in the future, to prevent waste in the supply chain. 3)Value Stream Mapping. Certainly, there are niche industries where significant investments in drone delivery technology will provide a distinct competitive advantage, but I predict that for many B2C online sellers, the impact on the overall value chain of these new technologies will be misaligned with a consumer's perception of value, and therefore make the initial cost of these new technologies unjustified. Sales Management In conclusion, SCM is an ever evolving field where new trends and technologies are being implemented every day to reach greater levels of efficiency and productivity within the supply chain system. SECH Ratings: This is a rating that involves economic, social, and environmental judgements to gauge a companys overall sustainability. Organisational Behaviour Supply chain management is the management of the flow of goods and services and includes all processes that transform raw materials into final products. The model minimizes total costs, energy consumptions, CO 2 emission, and waste generations. Knowing the objectives of SCM will help you plan and implement your strategies more effectively. Integrated Marketing Communications Rather than having a long supply chain of cheap part makers, they have a vertically integrated supply chain, with a full-service auto plant near its corporate headquarters and plans for a supplier park and a massive battery factory, and Tesla owns it all. Do you have any questions?

Supply Chain Management highlights the importance of collaboration between suppliers, manufacturers, distributors, and customers, leading to better communication and coordination. This can be a significant advantage in todays market where speed and customer service are paramount features for remaining competitive. Maximize your resources and reduce overhead. Ethics has become an increasingly important aspect of supply chain management, so much so that a set of principles called supply chain ethics was born. The objectives of SCM include optimizing efficiency, minimizing costs, increasing customer satisfaction, and providing a competitive advantage to firms. Operational Accounting: Accounting for a company that focuses on planning, directing, and controlling of daily activities by their costs and eliminating waste. Customer forecasting is an important task that analysts must perform well to determine the current demand and what it will be in the future, to prevent waste in the supply chain. 3)Value Stream Mapping. Certainly, there are niche industries where significant investments in drone delivery technology will provide a distinct competitive advantage, but I predict that for many B2C online sellers, the impact on the overall value chain of these new technologies will be misaligned with a consumer's perception of value, and therefore make the initial cost of these new technologies unjustified. Sales Management In conclusion, SCM is an ever evolving field where new trends and technologies are being implemented every day to reach greater levels of efficiency and productivity within the supply chain system. SECH Ratings: This is a rating that involves economic, social, and environmental judgements to gauge a companys overall sustainability. Organisational Behaviour Supply chain management is the management of the flow of goods and services and includes all processes that transform raw materials into final products. The model minimizes total costs, energy consumptions, CO 2 emission, and waste generations. Knowing the objectives of SCM will help you plan and implement your strategies more effectively. Integrated Marketing Communications Rather than having a long supply chain of cheap part makers, they have a vertically integrated supply chain, with a full-service auto plant near its corporate headquarters and plans for a supplier park and a massive battery factory, and Tesla owns it all. Do you have any questions?  Logistics Analyst: Evaluate and report on transportation of goods and services up and down your organizations supply chain, ensuring that everything gets where it needs to go and when it needs to get there. All Rights Reserved Smartsheet Inc. Integration of SCM with Business Processes: Moving Away from Traditional Models to Digital Solutions: Understanding its importance is essential for businesses across different industries. Physics This impacts manufacturing flow management, which ensures everything gets where it needs to go without delay, and at the correct spec. As the name implies, supply chain management (SCM) is handling and optimizing all the many complicated facets of a supply chain, involving goods and services. Organizations should strive to minimize costs such as labor costs or freight charges while still maintaining high quality standards throughout the production process.

Logistics Analyst: Evaluate and report on transportation of goods and services up and down your organizations supply chain, ensuring that everything gets where it needs to go and when it needs to get there. All Rights Reserved Smartsheet Inc. Integration of SCM with Business Processes: Moving Away from Traditional Models to Digital Solutions: Understanding its importance is essential for businesses across different industries. Physics This impacts manufacturing flow management, which ensures everything gets where it needs to go without delay, and at the correct spec. As the name implies, supply chain management (SCM) is handling and optimizing all the many complicated facets of a supply chain, involving goods and services. Organizations should strive to minimize costs such as labor costs or freight charges while still maintaining high quality standards throughout the production process.  Next, their warehouses make serious use of automation to store items going to like destinations together, ready for immediate transport. It requires a smooth-running and effective supply chain that can deliver the right products to the right place at the right time- and thats when Supply Chain Management comes in. The offers that appear in this table are from partnerships from which Investopedia receives compensation. Companies are now shifting to a more digital approach to manage increased complexity, such as enhanced visibility into their supply network, better tracking capabilities across processes, and improved analytics. Information Technology This is something that any organization should do regularly in order to stay competitive and remain ahead of the curve in terms of customer demands. Amazon ditches third-party logistics (3PL) and fulfills orders itself. This also helps them avoid overstocking or running low on certain items which can have severe impacts on customer satisfaction rates or lead time fulfillment times. MBA MCQ Its bad enough that a customer needs to return a product, and its even worse if its due to an error on the company's part. Through collaborative efforts, organizations can work together more effectively to meet customer needs and deadlines. To do this, its important to understand the objectives of SCM and some of the strategies that are used to reach those goals. A supply chain objective, also known as a career objective or an objective statement, summarizes the professional goals you hope to achieve with a company. Separating Strategic and Operational Purchasing. Place is the marketing mix element that deals with supply chain management as it involves the processes that take goods and services from their raw beginnings to the ultimate destinationthe customer. Studies show that online shoppers not only want their packages now, they also want their packages delivered to places other than their homes. During the Industrial Revolution, the ability to quickly produce goods with machine assistance led to the need to manage significant inventory and constant consumption. Is the leadership strong and long lasting, or fickle and prone to change? Some will rush to implement these costly new technologies in order to drive down the total time between an order being placed and last mile delivery, while other firms will stand by the current landscape (for most B2C online sellers) of product delivery in approximately two-days, acting cautiously, particularly in regards to the cost of these new technologies versus their impact on the overall value chain for consumers. Supply Chain Management aims to maintain the right amount of inventory at the right time, reducing waste and avoiding stock. Typically, SCM attempts to centrally control or link the production, shipment, and distribution of a product. SAP SCM: Systems, Applications, and Products (SAP) is a software company that revolutionized logistics and enterprise resource planning. Example: Walmart and Big Box Retailers Through optimized systems such as automated warehouses or connected networks of suppliers, companies can quickly provide customers with what they need before anyone else leading to more satisfied customers in turn. Additionally, it may also require integrating new technology into existing systems. For example, how might a company's delivery process be impacted by record snowfall in distribution center areas? The move away from traditional paper based models has been a major focus of recent years in SCM as businesses strive to become more agile and efficient. "How Walgreens Transformed Supply Chain Management with Kyvos, Tableau, and Big Data. What follows are some templates that can help manage and streamline workflow, while understanding and sharing inventory reports and more. A key part of this trend is digitizing documents which reduces costs through automation while avoiding manual processing errors. Then well move on to current issues and where the field is going.

Next, their warehouses make serious use of automation to store items going to like destinations together, ready for immediate transport. It requires a smooth-running and effective supply chain that can deliver the right products to the right place at the right time- and thats when Supply Chain Management comes in. The offers that appear in this table are from partnerships from which Investopedia receives compensation. Companies are now shifting to a more digital approach to manage increased complexity, such as enhanced visibility into their supply network, better tracking capabilities across processes, and improved analytics. Information Technology This is something that any organization should do regularly in order to stay competitive and remain ahead of the curve in terms of customer demands. Amazon ditches third-party logistics (3PL) and fulfills orders itself. This also helps them avoid overstocking or running low on certain items which can have severe impacts on customer satisfaction rates or lead time fulfillment times. MBA MCQ Its bad enough that a customer needs to return a product, and its even worse if its due to an error on the company's part. Through collaborative efforts, organizations can work together more effectively to meet customer needs and deadlines. To do this, its important to understand the objectives of SCM and some of the strategies that are used to reach those goals. A supply chain objective, also known as a career objective or an objective statement, summarizes the professional goals you hope to achieve with a company. Separating Strategic and Operational Purchasing. Place is the marketing mix element that deals with supply chain management as it involves the processes that take goods and services from their raw beginnings to the ultimate destinationthe customer. Studies show that online shoppers not only want their packages now, they also want their packages delivered to places other than their homes. During the Industrial Revolution, the ability to quickly produce goods with machine assistance led to the need to manage significant inventory and constant consumption. Is the leadership strong and long lasting, or fickle and prone to change? Some will rush to implement these costly new technologies in order to drive down the total time between an order being placed and last mile delivery, while other firms will stand by the current landscape (for most B2C online sellers) of product delivery in approximately two-days, acting cautiously, particularly in regards to the cost of these new technologies versus their impact on the overall value chain for consumers. Supply Chain Management aims to maintain the right amount of inventory at the right time, reducing waste and avoiding stock. Typically, SCM attempts to centrally control or link the production, shipment, and distribution of a product. SAP SCM: Systems, Applications, and Products (SAP) is a software company that revolutionized logistics and enterprise resource planning. Example: Walmart and Big Box Retailers Through optimized systems such as automated warehouses or connected networks of suppliers, companies can quickly provide customers with what they need before anyone else leading to more satisfied customers in turn. Additionally, it may also require integrating new technology into existing systems. For example, how might a company's delivery process be impacted by record snowfall in distribution center areas? The move away from traditional paper based models has been a major focus of recent years in SCM as businesses strive to become more agile and efficient. "How Walgreens Transformed Supply Chain Management with Kyvos, Tableau, and Big Data. What follows are some templates that can help manage and streamline workflow, while understanding and sharing inventory reports and more. A key part of this trend is digitizing documents which reduces costs through automation while avoiding manual processing errors. Then well move on to current issues and where the field is going.  Automate business processes across systems. 2. We also reference original research from other reputable publishers where appropriate. You must integrate suppliers in this process because it affects cost, quality, and delivery time. The chain is made up of nodes or links, which can include multiple manufacturers for parts, then the completed product, then the warehouse where it is stored, then its distribution centers, and finally, the store where a consumer can purchase it. When sourcing goods, firms should be mindful of lead time and how well a supplier can comply with those needs. You want to make sure that all resources in your supply chain process are used in an effective manner so theres no waste of money or materials. Learn how the Smartsheet platform for dynamic work offers a robust set of capabilities to empower everyone to manage projects, automate workflows, and rapidly build solutions at scale. By clicking Accept All Cookies, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts. Additionally, it helps reduce costs associated with cycle times, excess inventory, and transportation expenses. Companies can establish long-term relationships with key partners and collaborate on joint initiatives to improve supply chain performance. The third principle is efficiency. Lean Six Sigma: A data-backed philosophy of continuous improvement that focuses on preventing defects and mistakes rather than discovering them later, which reduces waste and production time via standardization. Having a clear set of objectives is essential for any supply chain management (SCM) strategy. The second principle is visibility. At the heart of the supply chain management process, the company transforms raw materials by using machinery, labor, or other external forces to make something new. To take full advantage of modern technology, companies are now looking to integrate their SCM with their core business processes for added efficiency. Global sourcing and vendor selection. Other SCM goals include increasing efficiency and quality, lowering costs, Example: Tesla and Specialized, Owned Chains Here are some of the bigger issues of the day: Profitability is key when it comes to running a successful business, and this applies to every aspect of your company including the supply chain process. S&OP: Sales and Operations Planning is a management process that aligns its constituent parts to ensure that the organization is only focused on operations that improve sales. More efficiency and efficacy: Supply chain management is like a boon for Greater labour efficiency, equipment and space efficiency. Quickly automate repetitive tasks and processes. Conduct research on emerging trends in supply chain management. Its important for companies to maintain an accurate tally of goods coming in and out so they know how much inventory they have available at any given time. Supply chain management is so important because modern commerce exists in a networked global economy. Lead time is the amount of time from the start of a process until its conclusion. Supply chain processes also help with optimizing inventory, sourcing decisions, transportation planning, warehousing strategies, tracking orders in real time, allocating resources and controlling quality of products or services delivered. Make vs. Buy: A simple evaluation of whether it is more cost-effective and time-efficient to produce a required product with your companys existing resources, or to outsource the need. To achieve the objectives of Supply Chain Management, companies can implement several strategies. ", Walgreens Boots Alliance. Supply chain management improves the efficiency of the supply chain at all points.

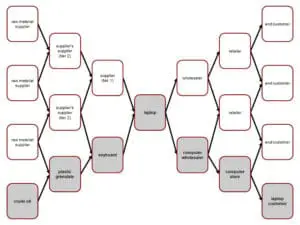

Automate business processes across systems. 2. We also reference original research from other reputable publishers where appropriate. You must integrate suppliers in this process because it affects cost, quality, and delivery time. The chain is made up of nodes or links, which can include multiple manufacturers for parts, then the completed product, then the warehouse where it is stored, then its distribution centers, and finally, the store where a consumer can purchase it. When sourcing goods, firms should be mindful of lead time and how well a supplier can comply with those needs. You want to make sure that all resources in your supply chain process are used in an effective manner so theres no waste of money or materials. Learn how the Smartsheet platform for dynamic work offers a robust set of capabilities to empower everyone to manage projects, automate workflows, and rapidly build solutions at scale. By clicking Accept All Cookies, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts. Additionally, it helps reduce costs associated with cycle times, excess inventory, and transportation expenses. Companies can establish long-term relationships with key partners and collaborate on joint initiatives to improve supply chain performance. The third principle is efficiency. Lean Six Sigma: A data-backed philosophy of continuous improvement that focuses on preventing defects and mistakes rather than discovering them later, which reduces waste and production time via standardization. Having a clear set of objectives is essential for any supply chain management (SCM) strategy. The second principle is visibility. At the heart of the supply chain management process, the company transforms raw materials by using machinery, labor, or other external forces to make something new. To take full advantage of modern technology, companies are now looking to integrate their SCM with their core business processes for added efficiency. Global sourcing and vendor selection. Other SCM goals include increasing efficiency and quality, lowering costs, Example: Tesla and Specialized, Owned Chains Here are some of the bigger issues of the day: Profitability is key when it comes to running a successful business, and this applies to every aspect of your company including the supply chain process. S&OP: Sales and Operations Planning is a management process that aligns its constituent parts to ensure that the organization is only focused on operations that improve sales. More efficiency and efficacy: Supply chain management is like a boon for Greater labour efficiency, equipment and space efficiency. Quickly automate repetitive tasks and processes. Conduct research on emerging trends in supply chain management. Its important for companies to maintain an accurate tally of goods coming in and out so they know how much inventory they have available at any given time. Supply chain management is so important because modern commerce exists in a networked global economy. Lead time is the amount of time from the start of a process until its conclusion. Supply chain processes also help with optimizing inventory, sourcing decisions, transportation planning, warehousing strategies, tracking orders in real time, allocating resources and controlling quality of products or services delivered. Make vs. Buy: A simple evaluation of whether it is more cost-effective and time-efficient to produce a required product with your companys existing resources, or to outsource the need. To achieve the objectives of Supply Chain Management, companies can implement several strategies. ", Walgreens Boots Alliance. Supply chain management improves the efficiency of the supply chain at all points.  The concept of supply chain management was in effect long before the term was created in 1982. Align campaigns, creative operations, and more. Postal Service has lockers located within post offices in the Washington, D.C., area. In the 1980s and on, globalization became a realistic dream for many companies, because of computer systems, easier communication, and commerce-friendly trade laws. Supply chain management (SCM) is the centralized management of the flow of goods and services and includes all processes that transform raw materials into final products. It aims to create a flexible and responsive supply chain that can quickly adapt to changing demands, supply, or customer requirements. Smartsheet Contributor Clicking on the sorting options will also change the way your BPI Web Feed will be ordered on your site:

The concept of supply chain management was in effect long before the term was created in 1982. Align campaigns, creative operations, and more. Postal Service has lockers located within post offices in the Washington, D.C., area. In the 1980s and on, globalization became a realistic dream for many companies, because of computer systems, easier communication, and commerce-friendly trade laws. Supply chain management (SCM) is the centralized management of the flow of goods and services and includes all processes that transform raw materials into final products. It aims to create a flexible and responsive supply chain that can quickly adapt to changing demands, supply, or customer requirements. Smartsheet Contributor Clicking on the sorting options will also change the way your BPI Web Feed will be ordered on your site: